A decade ago, three out of four of the Navy’s fighter and electronic warfare jets weren’t fit for combat, prompting the service to set a goal for 80-percent mission-capable rates. They got there in a year. Now the service is hoping to make similar magic happen again—this time with its surface and submarine fleets.

To pull it off, the Navy is looking at some of the lessons-from its aviation readiness crisis—like cutting down the amount of time a platform spends in scheduled maintenance.

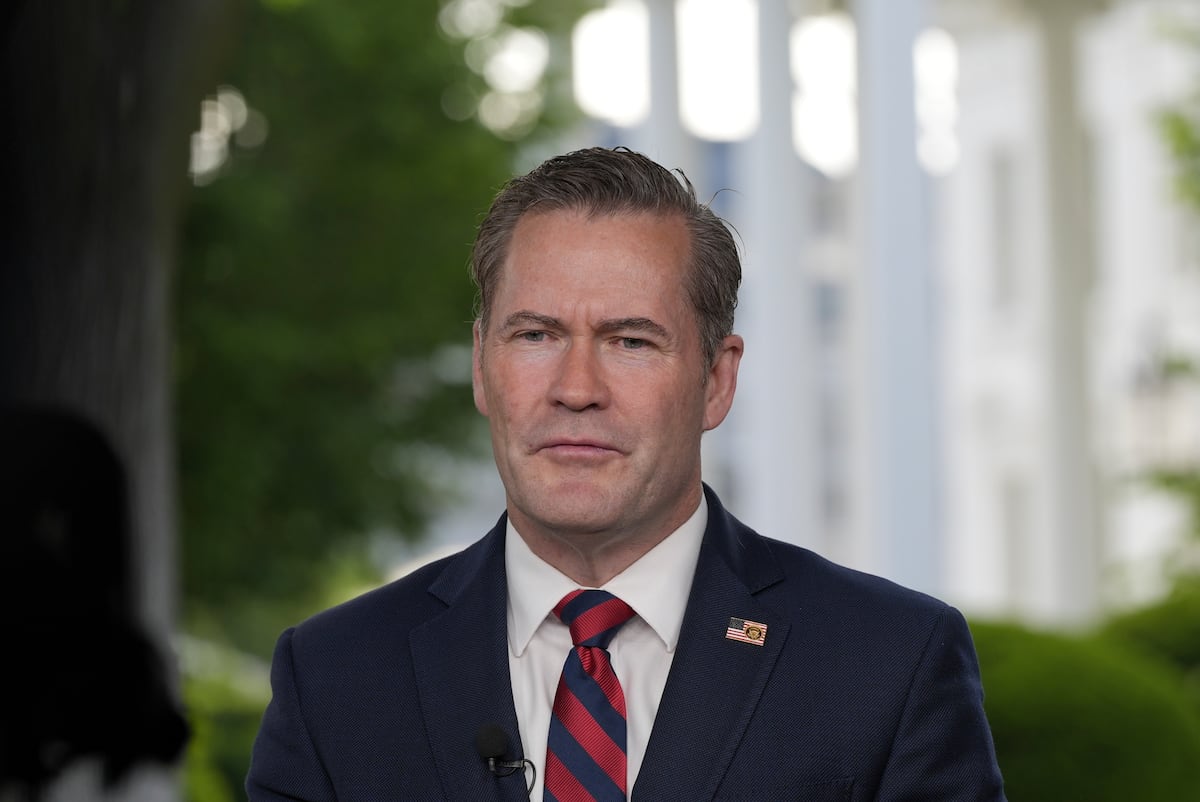

“By thinking, acting and operating differently, we decreased maintenance-hour turnaround time by 59 percent,” Adm. Jim Kilby, the acting chief of naval operations, said Monday at the Navy League’s Sea-Air-Space conference. “We reduced operational maintenance hours by 30 percent—an inspection that used to take 14 days was reduced to three days.”

Today, Kilby said, the surface force is sitting at 68-percent deployable, with the submarine force right behind at 67 percent. Carriers and carrier air wings sit at 70 percent.

Kilby’s predecessor, Adm. Lisa Franchetti, called 80 percent a “stretch goal.” But that doesn’t mean it’s far-fetched, Kilby said.

“It’s got to be aggressive to push us out of our comfort area,” he told reporters Monday. “And that’s what we found on the journey with aviation. We needed a goal that was not easy to obtain, and it forced us to look at our processes differently and maybe make some changes.”

Most of those changes involve doing better prep work for schedule maintenance, so that there are fewer surprises when a ship gets into the yard and opened up.

That means sitting down six months out and coming up with a game plan, Vice Adm. Brendan McLane, the head of Naval Surface Forces said during the conference

It also means ordering materials that take time to manufacture way ahead of time and stocking up on spare parts, so that there’s no wait on unexpected repairs.

“We saw several years ago that a significant amount of borrowed material is being ordered after the start,” said Vice Adm. Jim Downey, head of Naval Sea Systems Command. “It wasn’t a minor amount – it’s double digits, it was close to 50 percent.”

Buying those materials ahead of time can prevent the work stoppages that drag out schedules.

“So the big move there is, let’s go figure out how to buy contingent material for all the jobs we might need,” said Vice Adm. Robert Gaucher, head of Naval Submarine Forces. “So we’re now taking a just-in-case mentality to this, so that when we open up the [vessel] and we find out something we didn’t predict, we’ve already got the part ready.”

And while the Defense Department has instituted a sweeping hiring freeze, shipyard workers are notably exempt, which is good news for the Navy, because they need to hire 200,000 technicians over the next decade to get maintenance and shipbuilding where they’d like it, Downey said.

The Navy is also asking for industry to help them out. They want to get better at planning out availabilities and having the materials ready to repair anything that comes up, but they need private shipyard partners to also be forthcoming.

“I need them to be accurate in their planning and execution and not just say, ‘I haven’t busted my deadline yet,’ “ Kilby told reporters. “I’ve got to really understand that so we can adjust to that together as a team.”

Read the full article here

Leave a Reply