Among the many lessons of the Ukraine war is that traditional reactive logistics models are dangerously outdated.

Russia’s experience shows this. From February 2022’s 40-mile stalled convoy outside Kyiv to more recent ammunition shortages at the front, the Russian military’s sustainment failures have proven as devastating as any weapon system. Russia’s forces waited until units ran out of fuel before attempting resupply. They discovered parts shortages only when vehicles broke down. They tracked ammunition expenditure through manual processes that couldn’t keep pace with combat operations.

Meanwhile, Ukraine, with Western support, has demonstrated the power of data-driven logistics: using predictive analytics to forecast needs, position supplies, and maintain weapons systems before they fail. As I reflect on my final assignment leading Army Materiel Command, these contrasting approaches in Ukraine crystallize why the future of military logistics must be predictive, not reactive. The technology finally exists to make this transformation possible, and the stakes are too high to delay.

Tactical to strategic

The transformation to predictive logistics must happen at both the tactical and strategic levels.

At the tactical level, what I call “precision sustainment” is critical. Unit commanders need exactly the right equipment and supplies at the right time and place. They can only move so much with organic lift capabilities. Predictive logistics can optimize what gets moved, where, and when. For example, our systems can predict when vehicle components will likely fail, based on usage patterns and environmental conditions. This allows us to get replacement parts to units before breakdowns occur, maintaining combat power when it matters most.

The conflict in Ukraine has accelerated our progress in this area. Our security-assistance efforts gathered invaluable data about consumption rates, equipment reliability, and sustainment challenges in modern, high-intensity combat. This real-world laboratory helped validate our predictive models while highlighting areas needing improvement. The speed at which we’ve been able to adapt our support to Ukraine’s evolving needs demonstrates the potential of data-driven logistics.

While at Army Materiel Command, we began implementing the AMC Predictive Analytics Suite, a set of software tools that uses AI and other techniques to process vast amounts of data from multiple sources: maintenance records, usage patterns, environmental conditions, and operational tempo. The suite provides insights that would be impossible to derive manually. It enables us to anticipate when critical systems will likely fail and preposition spare parts and maintenance capabilities. We’re already seeing promising results, and we’re just scratching the surface of what’s possible.

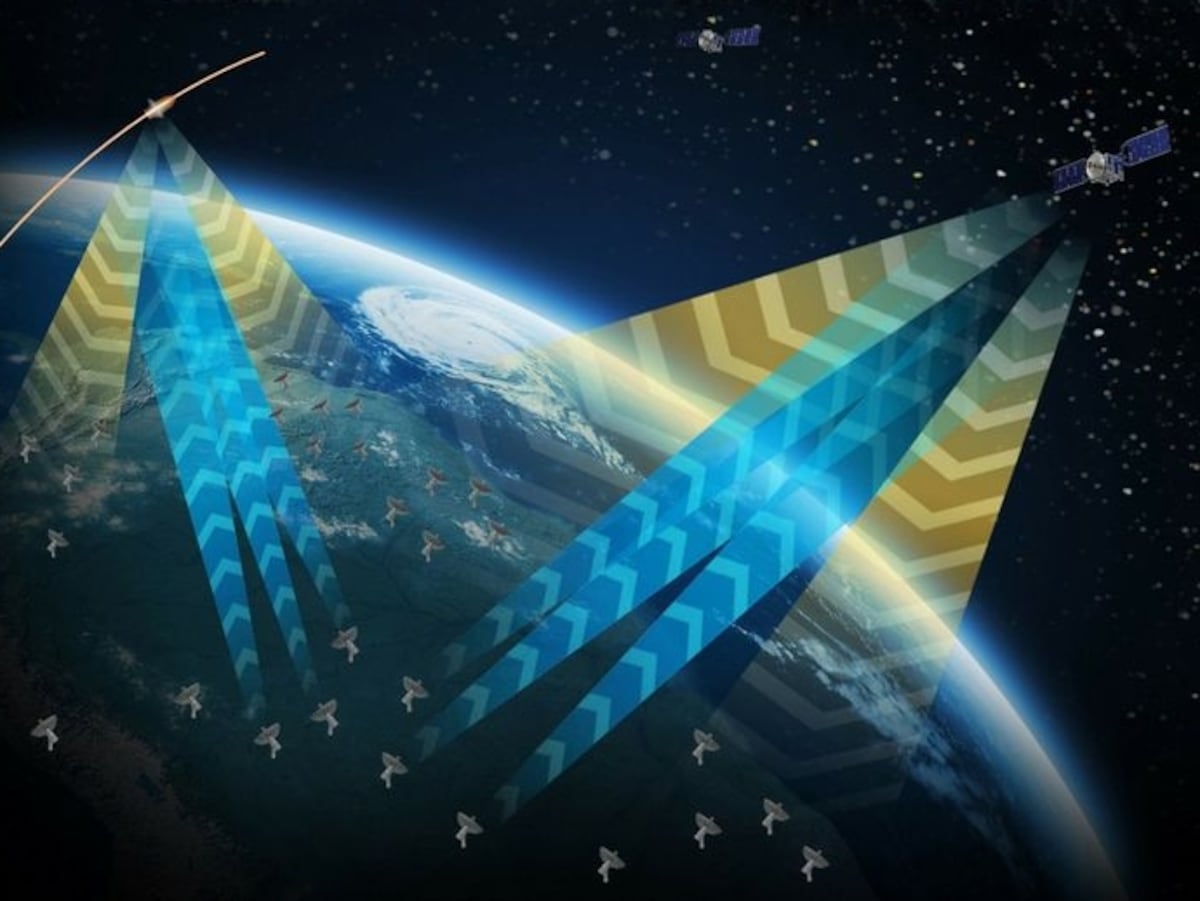

But the potential effects of predictive logistics are strategic as well. Modern conflict requires moving massive amounts of military resources across vast distances. In the Indo-Pacific theater alone, we must manage sustainment chains stretching over 5,000 miles from our strategic support areas to the tactical edge. This tyranny of distance makes predictive capabilities not just advantageous but essential.

Ultimately, predictive analytics could transform how we manage our organic industrial base and collaborate with commercial suppliers. Using data from sensors, maintenance records, usage patterns, and other sources, we can accurately forecast demand. This will allow us to make smarter decisions about production rates, storage locations, and distribution paths. It will enable our industrial base to anticipate demand rather than reacting to shortages.

Traditionally, we operated under a “factory to foxhole” model, pushing large volumes of supplies—often without ensuring they were the right ones. Today, with advanced, data-driven systems, we can—and we must—adopt a “foxhole to factory” perspective in which consumption at the tactical level informs and drives resupply efforts at the strategic level, ensuring precision and efficiency across the entire supply chain.

Think different

Technology alone isn’t enough. Transforming to predictive logistics requires changes in how we think about sustainment. We need sustainment leaders and planners who are as comfortable with data analytics as they are with traditional logistics planning. We need systems that can share data seamlessly across services and with allies. We also need acquisition processes that are agile enough to act on predictive insights. This cultural transformation may prove more challenging than the technological one.

The challenges are significant. Today’s systems weren’t designed for the level of data integration required. Security considerations complicate data sharing. And building predictive models that work across the complexity of global military operations is incredibly difficult. The sheer volume of data required—from maintenance records to supply chain metrics to operational plans—presents both technical and organizational challenges.

Yet the potential benefits are too great to ignore. Predictive logistics could dramatically improve our combat effectiveness while reducing costs. Instead of maintaining large “just in case” stockpiles, we can position smaller, more precise inventories exactly where they’re needed. Instead of rushing emergency resupply missions, we can plan deliberate movements based on accurate forecasts. The efficiency gains alone could save billions, but the real value lies in improved combat effectiveness.

What’s needed now is investment in three key areas. First, we must continue developing and refining our predictive analytics capabilities, including machine-learning models that can handle the complexity of military operations. Second, we need to modernize our data collection and sharing infrastructure to ensure we’re feeding these systems quality information. Finally, we must invest in training and developing the workforce that will implement and operate these systems.

As I look to the future, I’m convinced that mastering predictive logistics will be as crucial to military success as any weapon. The force that can best anticipate and meet its sustainment needs will have a decisive advantage.

Charles Hamilton, a retired U.S. Army lieutenant general, is the former commander of U.S. Army Materiel Command.

Read the full article here

Leave a Reply