Being a business major in college eventually paid off. After countless hours of work with Excel spreadsheets, I was actually able to determine that I could afford to shoot competitively or hunt, but not both. The money just wasn’t there. The United States Practical Shooting Association (USPSA) won out, and my dreams of a nice rack hanging up on the wall as well as vitamin-free meat were shunted to the side.

As I aged and money became a bit more plentiful, I was able to try my hand at deer hunting a few times. Still, since I come from a long line of cheap people, I was only hunting on OP (other people’s) land. Shall we say, success was minimal. My wife used to kid that I was only going camping and just took a rifle along.

In my late 50’s, a good friend of mine invited me to be a regular hunting partner with him. I would provide some of the labor and the cash — you know how that goes — and I would get to hunt on his property in return. I could even invite family on occasion. My son and I both scored our first deer the same evening, just minutes apart. My buddy, being the infinitely wise teacher that he is, smiled, told us both “congrats” and left us to figure out what to do next. Thank God for all those YouTube videos we’d watched.

We’ve learned a lot of things in the 60 or 70 deer we’ve harvested since then. We were shown how to use branch trimmers to cut through the rib cage and the pelvis, making the rest of the processing much easier and quicker.

Much of that on-the-job training has come from a ranch foreman who had cleaned and skinned countless deer. I swear that man can field dress, cape and quarter a deer in about four minutes. We’re down to about 30 minutes an animal for all the above. Then, he pitches in with blades and fur flying everywhere so we can go get dinner in a reasonable amount of time.

While he has been an invaluable source of information regarding technique, he has probably taught us just as much about the tools needed for the job. Which brings us to the fun part. We’re guys — we like toys. Sorry, I meant gear. Good professional quality gear, right? In this case, we’re talking about knives. Not the $17 special from Wally World, but something that would do a good job on an animal just harvested to feed your family. A knife that will stay sharp longer than a few seconds of cutting.

We’ve tried many different kinds of knives over the years. Some would have made Rambo proud. Some turned out to be too small to do a decent job on fingernails. Once again, we’ll defer to the ranch foreman and what has worked for him.

A TOP Guide

Most of his working blades fit into a pattern. They tend to have blades somewhere between 3.5” and 4.5” in length. We saw blade styles that ran the gamut from clip blades like our ancient Schrade folder to a Case Folder that was more of a Saber Clip and a Muley Skinner (officially a Skinner blade style — imagine that) from TOPS knives.

All of them have well-pointed tips to help us break the skin. They frequently feature a slight drop to the point to keep them away from things we didn’t want perforated.

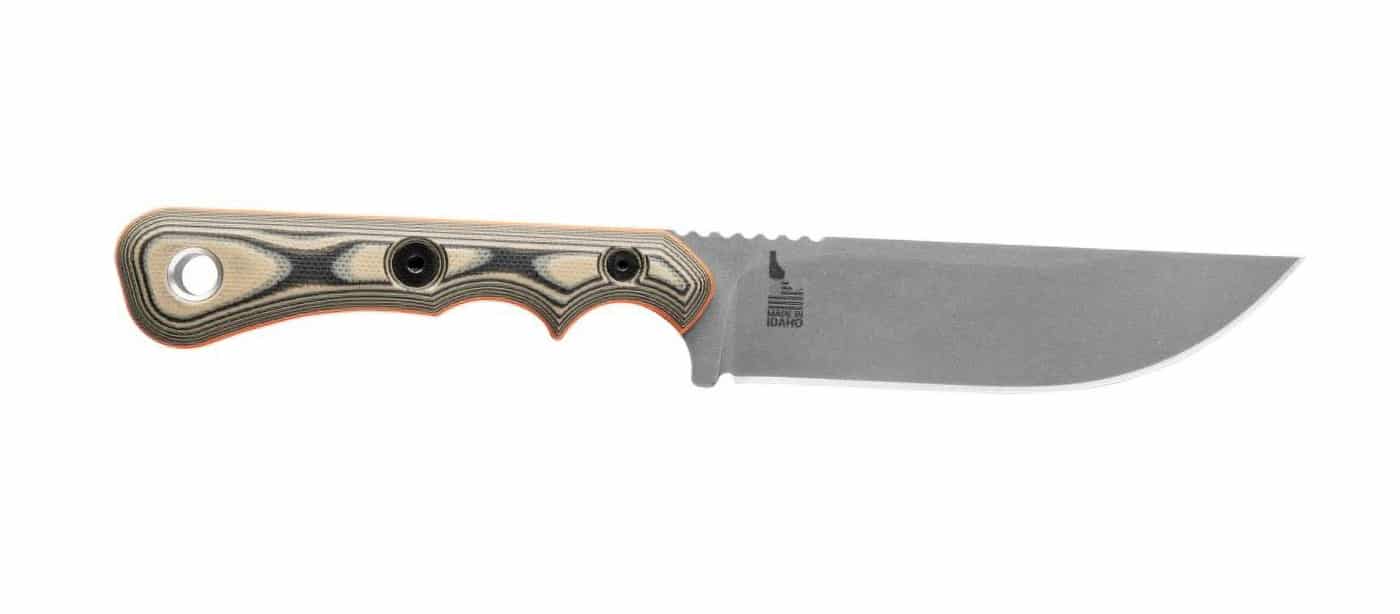

Designed by Leo Espinoza and produced at their factory in eastern Idaho, the TOPS Knives Muley Skinner may be our favorite, and we’ll use it for additional info. The Muley Skinner starts with the straight spine, a very sharp point and the curved edge expected in a skinning blade.

Total length on the knife is 8.75” with a 4.5” cutting edge. So dimensioned, we found this knife short enough to maneuver for field dressing while still long enough to have a worthwhile stroke for caping.

The grips are tan and black G10 scales with orange G10 liners — you’re not going to lose this knife when you set it down in the leaves. Held onto the .13”-width blade by four Torx screws, the grip handles also sport a ring for a lanyard — something that can come in handy with slippery or cold hands. The handle is undercut with finger grooves leaving the user with a lightweight, secure hold.

As with most TOPS blades, the steel is made from 154CM steel. This alloy adds many minerals in the composition to create the blade we were using. Carbon is mixed in for increased edge retention, hardness and tensile strength, and to improve resistance to corrosion and wear. The chromium also increases hardness and tensile strength. Manganese and vanadium also add strength and improve the heat treatment process. They also add molybdenum, silicon, phosphorous, sulfur and tungsten.

The end result is a hard steel with a Rockwell rating of 60-61 HRC. They double temper their steel to make it hard and very resistant to chipping, while still allowing excellent edge retention.

The sheath is black kydex and of a style that provides a secure grip on the knife. We’ve had knives in the past that would slip out of their leather sheath if not handled properly. This one won’t.

Conclusion

We have several guys in our group who always visit the TOPS booth at SHOT Show. That always seems to cost us money. We have used quite a few of their designs as we process our deer each December. In doing so, we have been amazed at how long they held their edge. We commonly get multiple animals done with each blade. Seems like a good deal to me. MSRP of the Muley Skinner is $300.

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in!

Read the full article here

Leave a Reply