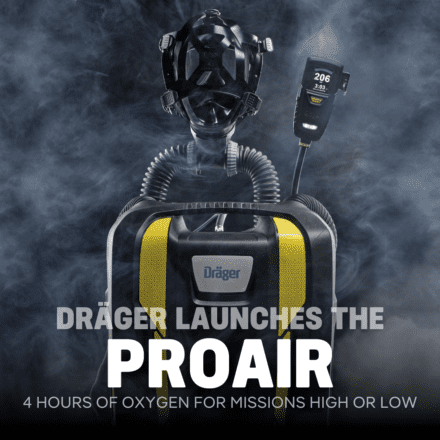

Advanced, Four-Hour Breathing Apparatus for Federal Government Operations in Extreme Conditions

• Closed-circuit breathing Apparatus

• CO2 Scrubbing Technology

• Prolonged Breathing Comfort

• Customizable Cooling Options

Houston, Texas – March 04, 2025 – Dräger, a global leader in safetytechnology, proudly unveils the NIOSH-certified ProAir, an advanced closed-circuit breathing apparatus (CCBA) designed to provide a continuous oxygen supply for up to four hours. Leveraging over a century of expertise in breathing apparatus technology, this innovative solution is set to transform Federal Government operations in hazardous environments, including below-deck ship incidents, confined spaces, subterranean operations, and HAZMAT operations.

The ProAir can enhance operational readiness for federal agencies, including the armed forces, law enforcement, emergency responders, and environmental protection agencies. By providing an uninterrupted oxygen supply, the ProAir enables personnel to focus on high-risk situations, such as search and rescue missions, decontamination efforts, and HAZMAT response, alongside other critical tasks.

David Warnacut, U.S. Marine and Dräger Product Manager, states, “In high-stakes operations, having dependable and effective equipment is essential. The ProAir provides access to safe, breathable oxygen for extended periods across various operations. This enduring commitment underscores Dräger’s dedication to enhancing the safety and effectiveness of our Federal agents and armed forces in the field.”

Adding Time to Critical Missions

The ProAir represents a significant advancement in personal safety gear, providing extended respiratory protection under some of the most challenging conditions. Designed to complement traditional SCBAs, the ProAir maximizes operational capabilities by eliminatingthe need for frequent cylinder changes during prolonged engagements. This additional time helps federal personnel to consolidate focus, complete intricate tasks without interruption, confidently navigate lengthy routes, and handle emergencies without worrying about the clock. By maximizing crucial operational time, the ProAir helpsfederal teams carry out their missions, increasing the safety and efficiency of high-stakes scenarios.

Innovative Scrubbing and Cooling Technology

The ProAir incorporates a proprietary carbon dioxide scrubber embedded in a positive pressure breathing circuit. This technology efficiently removes carbon dioxide and enriches the air with oxygen, removing the reliance on bulky air cylinders. The new RFID chip on the canister enables the ProAir to track the soda lime’s life.

Expanding its versatility, the ProAir introduces two advanced cooling options: the Ice Cooler with durable ice packs and the groundbreaking Phase Change Material (PCM) system, making its debut in North America. The Ice Cooler offers an improved user experience by containing the melted water inside the ice pack. Meanwhile, the PCM system utilizes paraffin wax sheets that require no freezing, offeringenhanced readiness and reliability, marking a significant advancement in CCBA technology.

Securing the Lower Decks

The ProAir extends operational time for responders handling below-deck emergencies, where rapid response and sustained action are critical. Its advanced air management system helps service membershandle long and hazardous tasks effectively, reducing risks from exposure to smoke and harmful fumes. This is crucial for maintaining crew safety and readiness during a maritime crisis, giving additional time to address hazards and navigate complex below-deck configurations.

Confined Space and Sub-T Operations

The ProAir excels in subterranean (Sub-T) environments, where confined spaces and hazardous air conditions can pose significant risks. This solution helps personnel breathe safely and in underground facilities, tunnels, and passageways, allowing teams to execute intricate maneuvers, navigate treacherous terrains, and respond to emergencies confidently. Its robust, extended air supply minimizes the need for frequent cylinder changes, offering continuous protection.

HAZMAT Resilience

The ProAir is purpose-built to help counter HAZMAT threats, providing critical breathing protection during attacks, rescue missions, decontamination, and containment operations. Unlike traditional SCBAs that are limited to 45-60 minutes, the ProAir extends operational time with up to four hours of breathable air, reducing cylinder changeovers and minimizing downtime. This added capacity allows responders to remain in hazardous environments for extended periods, supporting sustained containment, decontamination, and cleanup efforts while improving overall operational efficiency.

Innovative Features for Enhanced Performance:

? Withstands Flames: The ProAir endures direct exposure to flames up to 1,742°F, meeting the highest safety and performance standards.

? Boosts Visibility: Enhances team awareness with Buddy Lights displaying cylinder pressure.

? Handles Extremes: Built to resist high temperatures, dust, debris, and sparks while ensuring agility with advanced ergonomic relief.

? Simplifies Maintenance: Easy, tool-free disassembly and servicing of the CCBA.

? Delivers Instant Updates: View critical supply status and alerts—such as cylinder pressure and time to whistle—on the palm-sized Electronic Control Unit (ECU).

? Enhances Communication: Stay connected with integrated radio features and voice amplification for clear communication in challenging environments.

? Tracks Usage: Leverage the built-in RFID chip to monitor soda lime life and streamline maintenance.

For more information, please visit the Dräger BG ProAir webpage.

You can skip to the end and leave a response. Pinging is currently not allowed.

Read the full article here

Leave a Reply